OCMI-OTG is world’s leading company operating at a global level in the field of machinery for the production of tubular glassware for the pharmaceutical industry and hollow glass processing machinery, as confirmed by the great number of installations worldwide.

DISCOVER THE OCMI WORLD

PRODUCTS

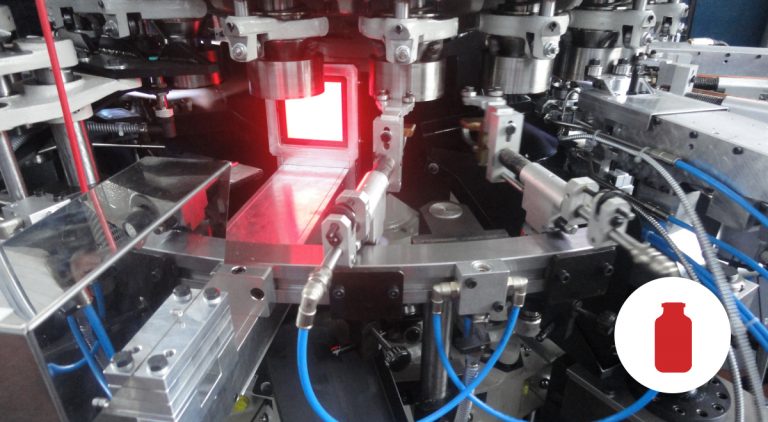

LF520

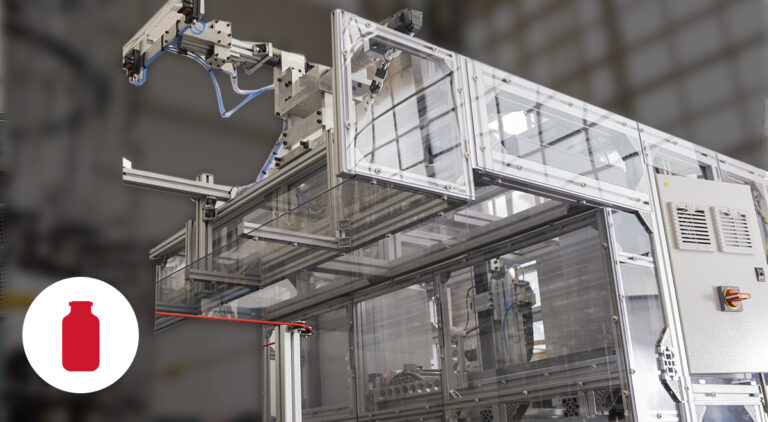

OPTIVIAL

PM-V

ROBOGLASS

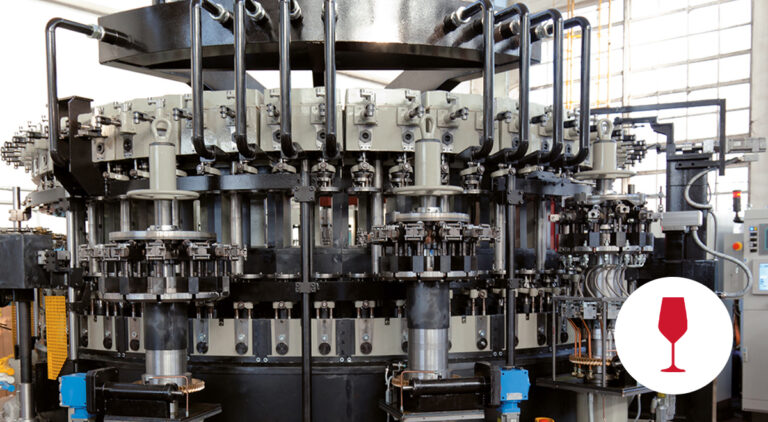

ATL/4

SA

PAS

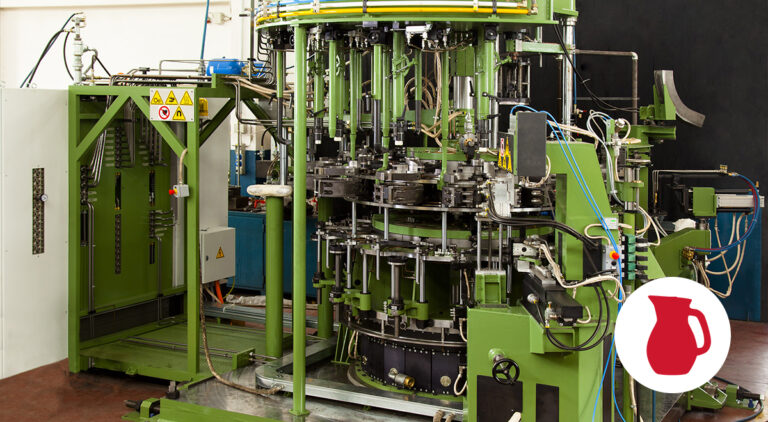

GLASS BLOCKS PRODUCTION LINE

GLASS INSULATORS PRODUCTION LINE

SERVICES

Research and Development

R&D teams of OCMI factories committed to find solutions to constantly improve efficiency of production lines

Preliminary Advice

Consulting about preliminary steps to build-up a factory for tubular glass containers production

After-Sales service

Skilled and experienced technical staff available to support customers in case of any technical issue even through remote connection

Production training

Glass processing specialists available to train customer’s operators to get the best quality products

Fully Equipped Facilities

Possibility to organize inspections, tests, F.A.T. in all OCMI European facilities

Quality Control

Most accurate control performed on all mechanical, pneumatic, electronic components before assembly

Spare Parts

Dedicated office for spare parts sales and possibility to send assembly drawings of complete lines through web service upon customer’s request.

FACTORIES

OCMI was established in 1978 with the aim of developing the GUSTI glass processing machines division.